Product Description

The ES-7000 AC is a portable, rugged, single-function EMI system for inspecting drill pipe and tubing in extreme environments. Transverse flaw detection functio is standard on the unit. Its portable design allows the EMI Unit to be operated at the rig-site or in a pipe yard. The ES-7000 C is designed to meet most industry specifications set forth by API, DS-1, etc.

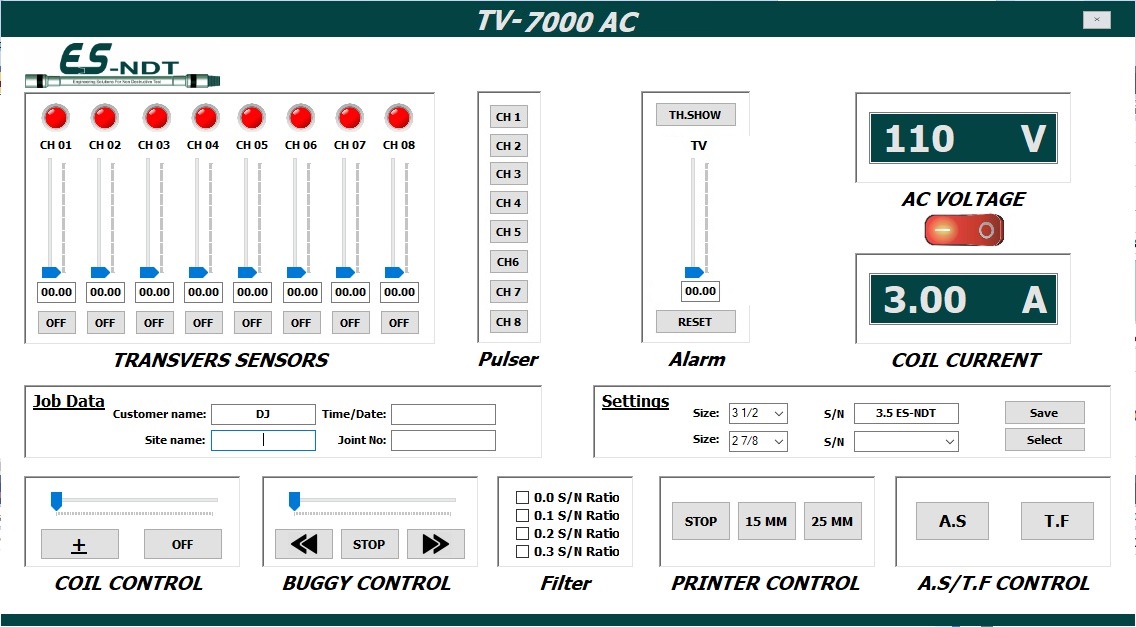

ES-7000 AC

Specifications

Technical and Performance Data

Capacity:

2 3/8" to 6 5/8" O.D. drill pipe

Functions:

Transverse flaw detection (MFL)

Data Acquisition:

Thermal printer or optional DAQTech III™ computer data acquisition system

Production Rate:

Up to 150 ft /minute

Inspection Criteria:

The ES-7000 AC is designed to meet most industry specifications (i.e. API, DS-1, etc.)

Major Components:

TRX electronics console

Ultrasonic scanning wheel

Variable speed electric pipe rotators

Calibration standards (sizes optional)

Available Options:

Electronics console

Power, signal, and buggy drive cables

High speed buggy drive with variable speed DC motors

Powerful DC magnetizing coils

Air jack set (standard or Hi-Low models available)

Buggy heads (sizes optional)

Calibration standards (sizes optional)

DAQTech III™ computer data acquisition system (optional)

Method of Operation

The ES-7000 AC is a portable, rugged, single-function EMI system for inspecting drill pipe and tubing in extreme environments. Transverse flaw detection functio is standard on the EZW. Its portable design allows the EMI Unit to be operated at the rig-site or in a pipe yard. The ES-7000 C is designed to meet most industry specifications set forth by API, DS-1, etc.