Product Description

The TV-W.TH 7000 AC is a portable, rugged, Dual-function EMI system for inspecting drill pipe and tubing in extreme environments with Auto Scan option which enable the operator to make the test automatically and Tracing Function make the drive stopped automatically when detect the required signal . Transverse flaw detection and TRUEWALL™ solid state (Hall effect) wall monitoring functions are standard on the unit. . All cable connections are mounted on the top instrumentation panel. The cables have 90-degree connectors to eliminate bending. The TV-W.TH 7000 AC is designed to meet most industry specifications set forth by API, DS-1, etc

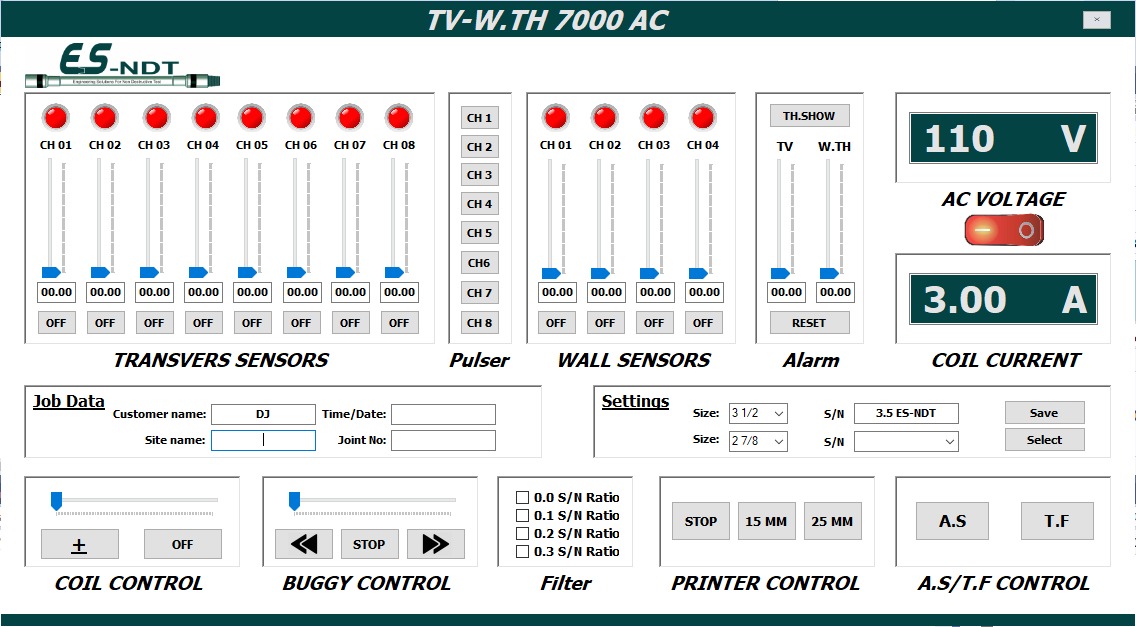

TV-W.TH 7000 AC

Specifications

Technical and Performance Data

Capacity:

2 3/8" to 6 5/8" O.D. drill pipe

Functions:

Transverse flaw

detection (MFL)

TRUEWALL™ magnetic wall thickness monitoring (MFD)

Data Acquisition:

Data acquisition system with ruggedized laptop computer (all functions performed on computer with multi-color data display)

Production Rate:

Up to 150 ft /minute

Major Components:

Electronics console

Ruggedized laptop computer with software

Power and signal cables

Powerful magnetizing coil

Inspection canister

Detector insert kits with split detector and tubing standards (sizes optional)

Horizontal rack for pipe yard inspection (optional)

Small canister with no split detector (optional)

Method of Operation

The TV-W.TH 7000 AC is a portable, rugged, dual-function EMI system for inspecting drill pipe and tubing in extreme environments. Transverse flaw detection and TRUEWALL™ solid state (Hall effect) wall monitoring functions are standard on the unit. Its portable design allows the EMI Unit to be operated at the rig-site or in a pipe yard. The TV-W.TH 7000 AC is designed to meet most industry specifications set forth by API, DS-1, etc